Patents and technologies

Eight innovative and unique patents. Very few companies in this field may boast a comparable spirit of innovation and performance, such a well defined vision of the future. In the last forty years Abate Basilio has been changing the market of the injection moulds of plastic material, allowing companies to offer improved, safer and more efficient products.

The company experience together with its research ensure an on-going technical development aimed at offering advanced and effective solutions to its customers in the field of injection moulds for packaging. Our expert knowledge of materials and their applications allows us to offer incomparable, reliable and efficient production systems.

Our patented technologies include mould cooling, centring, in-mould handle assembly, modularity of the cavities, ejection of the product and the design of new containers with customized closing systems specific for food and industrial purpose.

Our patents offer our customers greater advantages compared to the competition.

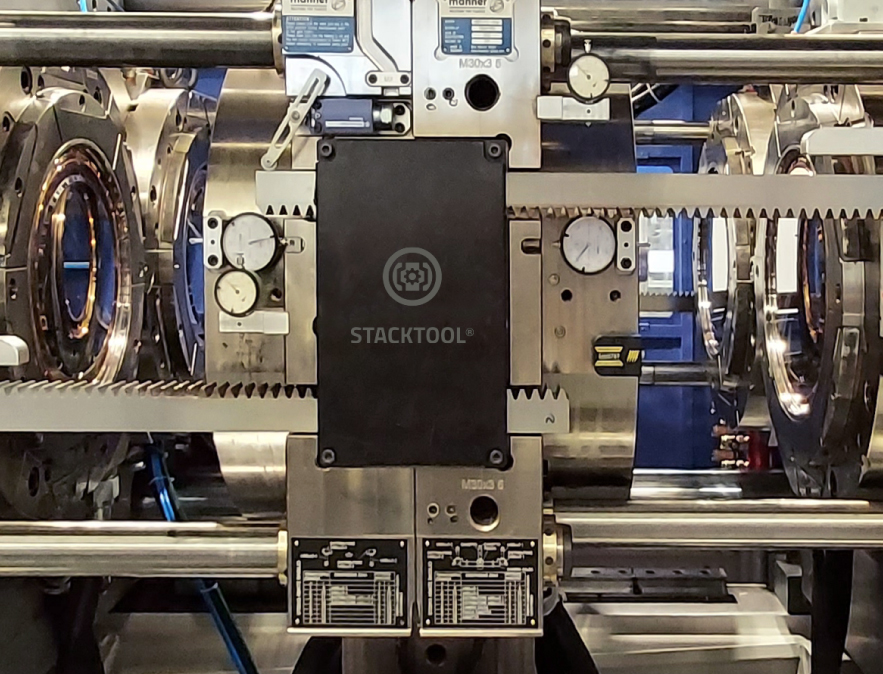

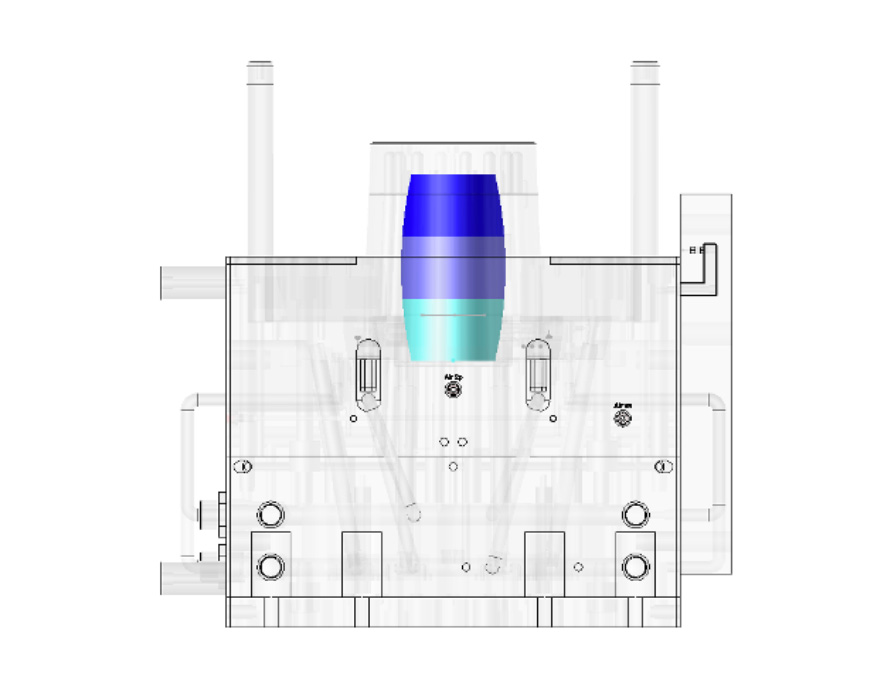

High-performance multi-platen modular mould.

The Stacktool is an injection moulding system designed to increase production while guaranteeing repeatability and part quality.

The use of moulds with several moulding surfaces allows the production of the same injection moulding machine to be multiplied. Stacktool technology, also known as sandwich technology, therefore ensures increased production while reducing costs.

Optimized technology

Double centred mould with movement wear recovery

The new Duplex® mould has several advantages that set it apart:

a) Reliability

b) Ease of use

c) Reduced maintenance

d) Increased service life

e) Decreased environmental impact

Worldwide registered patent

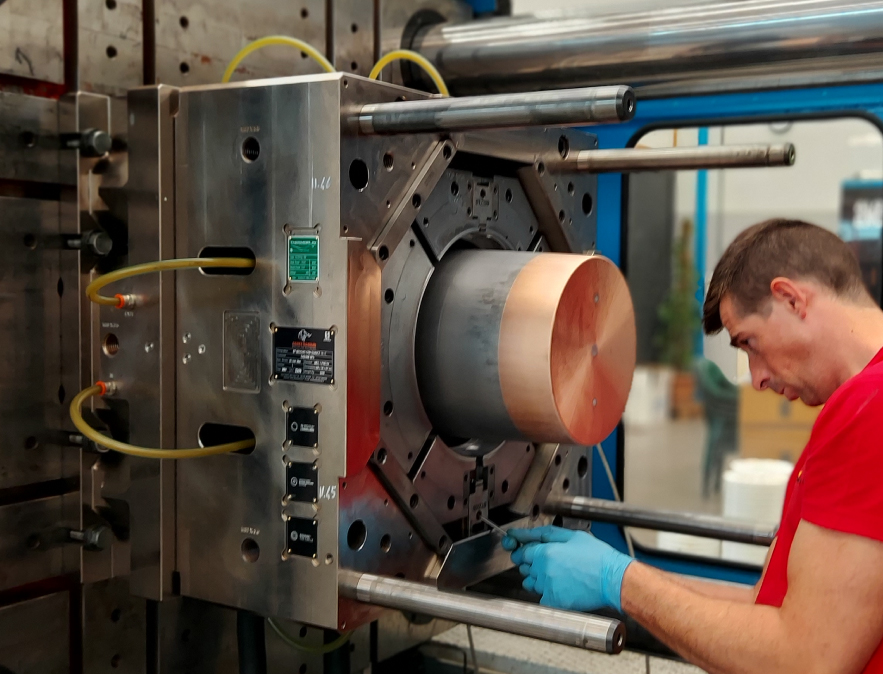

injection and compression system

The injection compression technology exploits two different stages of the injection machine to form the piece. The first stage consists of the injection trough the screw of the IMM while the second stage relates to the plasticization of the piece, due to the surfaces of the mould coming in contact with each other during the closing of the IMM. This second stage is the innovative part of the process.

Optimized technology

handle moulding and assembly

onto the container directly carried out into the mould.

The IMA technology is protected by a worldwide patent registered by Abate Basilio and has been specifically designed for containers with handles. The in-mould handle assembly does not require any labour and it allows for the optimization of the process 24/7.

The advantages are evident: there is no need for additional moulds and presses, the in-mould mechanical system excludes any error, provides highest flexibility as well as energy savings and customization of the handle for easy storage and moulding.

Worldwide registered patent

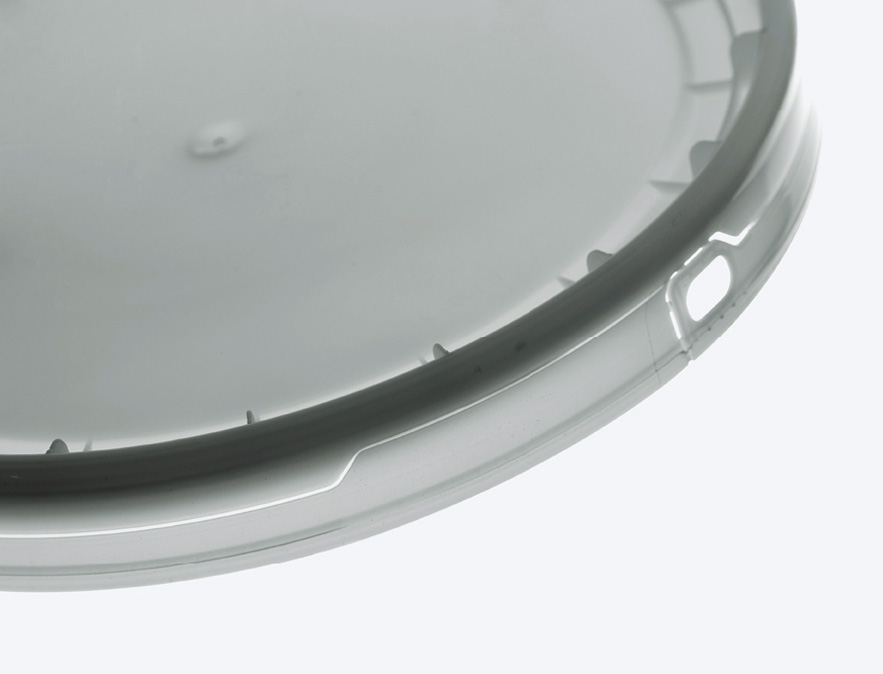

container with double lock lid and tear-off band

A new closing system with double or triple lock features for buckets and containers developed by Abate Basilio. The mould obtained using the Quadrowings technology allows the manufacture of products with a sealing closure, in stable stacks (up to 9 buckets), which can withstand any drop test up to 1.50m.

The customization provided by the company allows to incorporate tear-off bands, tamper proof systems and geometry without any crease.

Worldwide registered patent

container with triple lock lid and tear-off band

A new assembly comprising innovative container and lid made of plastic material which is the result of 25 years of research and development in the field of closing systems for special containers.

Triplock® combines easy closing feature of the lid – assured by foldable wings providing incomparable drop resistance and tamper proof properties as well as tightness features enhanced by triple lock technology.

With the same weight of the container/lid, this closing system ensures better performance than other systems currently on the market.

Worldwide registered patent

labelling during the moulding process

This technology has been developed and improved by Abate Basilio over the last 25 years; It allows for the optimisation of the production cycle by applying the label onto the container directly during the injection and moulding process. Optimized technology

IML technology ensures excellent features and advantages for the food and chemical industry.

cavity change on the same mould

Abate Basilio has developed a new system of modular mould called FlexoMould. This proprietary technology allows us to change the format in a completely safe manner through the movements of the machine platen without any risks for the moulds and the operators.

FlexoMould ensures a fast change and set up of other moulding modules in order to manufacture different products on the same mould without the need to remove the mould from the machine platens. Furthermore the mould obtained with this technology allows to take advantage of the automation in the best way.

Optimized technology

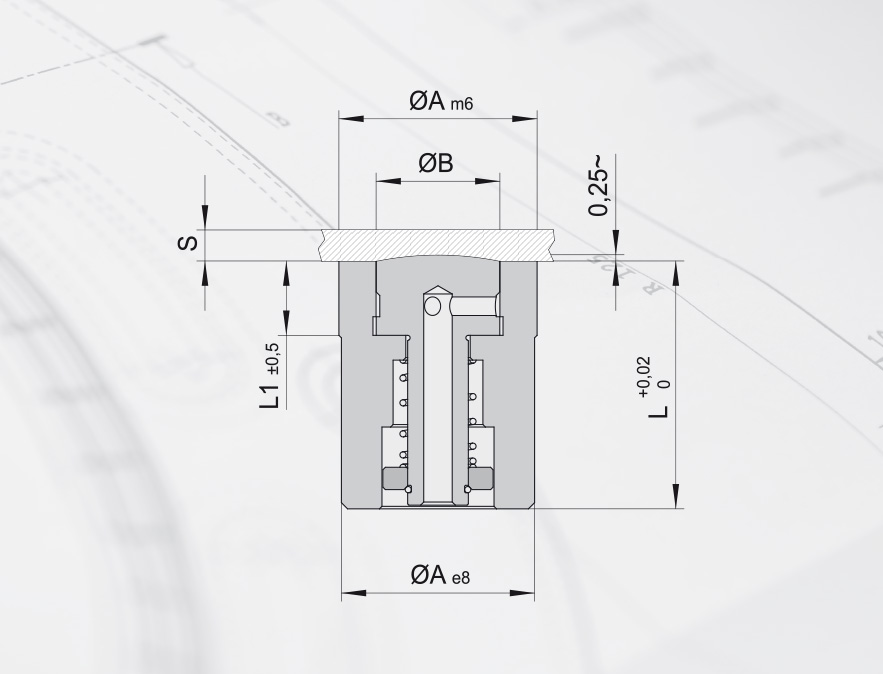

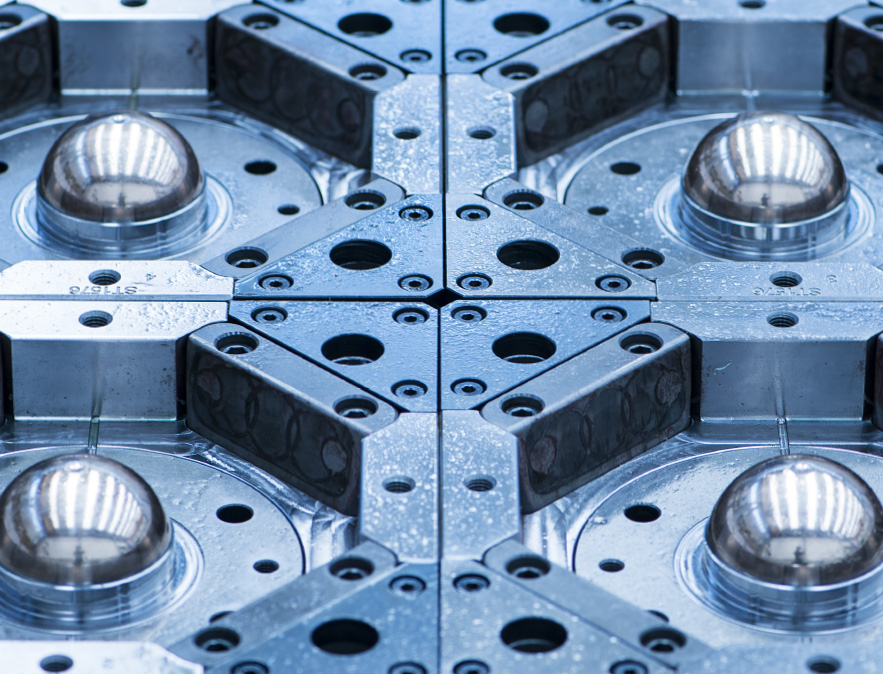

advanced system to centre the moulds

The Square the Circle technology is an exclusive patent owned by Abate Basilio. This system to centre the moulds is the pride of our company and is now present on production lines all over the world. Versatility is the main feature of this technology.

Worldwide registered patent

enhanced cooling system

The Innercore Extra Cooling System is a technology covered by an exclusive patent which is the result of extensive planning and development work which lasted many years; this system allows the cooling down of truncated cone-shaped moulds.

Worldwide registered patent

ejection valve with a safe closure

This valve, now famous throughout the world, is covered by a patent owned by Abate Basilio which ensures greater reliability to the moulds.

This valve with a safe closure eliminates jamming and the consequent back flow of plastic into the valve and its air supply channels, thus avoiding prolonged machine downtime.

Worldwide registered patent